Understanding Radiation Glass Technology

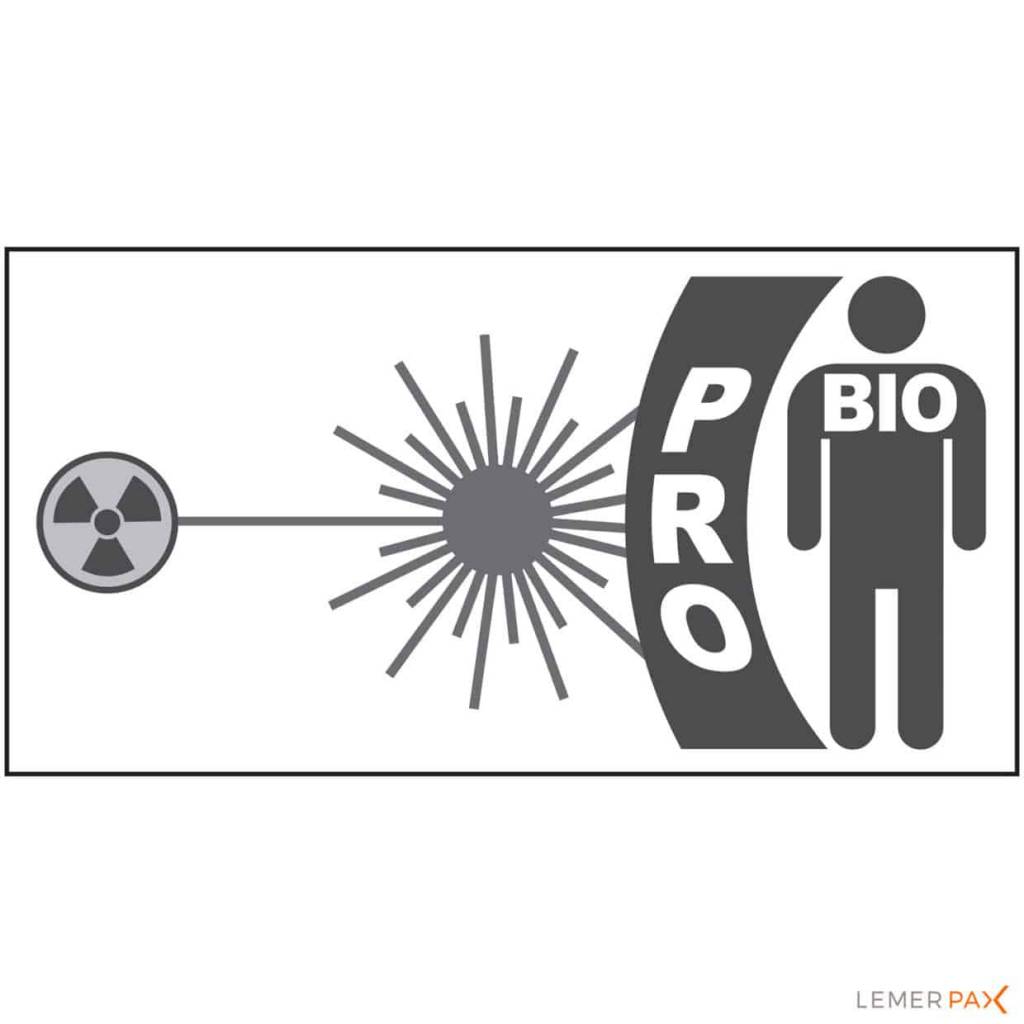

Radiation glass technology plays a crucial role in ensuring safety across medical, industrial, and research fields. As exposure to ionizing radiation poses significant health risks, advancements in this technology aim to enhance protection while maintaining optimal visibility and durability.

Traditionally, radiation shielding was achieved using leaded glass, known for its dense composition that effectively absorbs harmful radiation. However, the increasing demand for lightweight and environmentally friendly alternatives has led to significant improvements in the materials and manufacturing processes of radiation shielding glass.

Key Innovations in Radiation Glass Technology

Recent advancements in radiation glass technology have addressed several challenges, including enhanced protective capabilities, environmental sustainability, and improved optical properties. Below are some of the most notable developments:

- Lead-Free Radiation Glass: With rising concerns over lead toxicity, manufacturers have developed lead-free shielding glass. These alternatives use advanced materials such as bismuth and tungsten, which provide effective radiation attenuation while reducing environmental impact.

- Enhanced Optical Clarity: Early radiation glass was often criticized for its yellowish tint, which could impact visibility. Newer formulations offer superior optical clarity, ensuring that medical professionals and technicians can operate with better precision.

- Increased Durability: Modern radiation glass features advanced coatings and reinforced structures, making them more resistant to scratches, impact, and wear, thus extending their lifespan.

- Lightweight Design: Traditional leaded glass is heavy, making installation and maintenance cumbersome. Innovations in material sciences have led to the development of lightweight yet highly effective radiation-shielding glass.

- Customizable Solutions: Radiation glass can now be tailored to specific operational requirements, with custom sizes, thicknesses, and levels of protection available for various applications.

Applications of Advanced Radiation Glass

Innovations in radiation glass technology have expanded its applications across multiple sectors, ensuring safety and efficiency in different environments:

- Medical Imaging and Radiology: Hospitals and clinics use radiation shielding glass in X-ray rooms, CT scan facilities, and nuclear medicine labs to protect both healthcare professionals and patients.

- Nuclear Industry: Radiation glass is essential in nuclear plants and laboratories, where personnel work near radioactive materials. It provides visibility while minimizing radiation exposure.

- Industrial and Research Laboratories: Industries dealing with non-destructive testing, sterilization, and radiation experiments rely on high-performing radiation glass for safety and accuracy.

- Aerospace and Defense: In high-radiation environments such as space exploration and defense applications, specialized shielding glass ensures protection without compromising functionality.

The Role of Coatings and Multi-Layer Glass Structures

In addition to material advancements, coating technologies and multi-layer glass structures have greatly enhanced radiation protection efficiency. Anti-reflective coatings reduce glare while ensuring optimal light transmission, which is particularly useful in medical and industrial settings. Similarly, multi-layer glass structures enable a combination of protective layers, offering better resistance against impact and a wider range of radiation shielding capabilities.

As industries demand improved performance and cost-effective solutions, these additional features help extend the lifespan of radiation glass while ensuring highest safety standards.

Choosing the Right Radiation Glass for Your Needs

When selecting radiation glass, several factors must be considered to ensure optimal protection and performance. These include:

- Radiation Attenuation Levels: The level of required protection depends on the type and intensity of radiation exposure in a particular setting.

- Thickness and Weight: While thicker glass may offer stronger shielding, advancements in materials now allow for effective protection even with reduced thickness.

- Optical Clarity: Ensuring clear visibility is essential in medical and industrial applications where precision is required.

- Installation and Maintenance: Some modern radiation glass options are easier to install and maintain, making them more user-friendly.

Those looking for high-quality radiation glass should consider manufacturers that emphasize durability, sustainability, and performance in their products.

The Future of Radiation Glass Technology

As technological advancements continue, future developments in radiation glass aim to enhance efficiency, sustainability, and user adaptability. Researchers are exploring materials that further reduce weight and improve transparency while maintaining high levels of radiation protection. Smart glass technologies with adjustable shielding capabilities are also gaining interest, providing adaptive solutions based on radiation exposure levels.

Overall, innovations in radiation glass technology continue to make workplaces safer and more efficient. With improvements in material science, manufacturing techniques, and environmental consciousness, the next generation of radiation shielding solutions promises better protection and performance across various industries.